Manufacturing Processes

Home > Manufacturing Processes

Foam In Place Gasket Technology

Foam In Place Gasket (FIPG) technology is an automated system that allows eLuminaire to achieve IP ratings that would otherwise require more components and additional manufacturing labor. The FIPG technology is a costly automated system that eLuminaire saw as a clear advantage against the typical hand laid gaskets used by many competitors.

The process involves dispensing German made RAKU-PUR® liquid onto our fixtures directly. This two-part polyurethane system contains no solvents, plasticizers or halogenated hydrocarbons. It cures at room temperature directly on the fixture. It is characterized by:

-

Well formed integral skin and reliable sealing

-

Listed UL50

-

Very low water absorption

-

low assembly resistance

-

Good and prompt compression recovery

-

Operating temperature from -40˚C to 160˚C

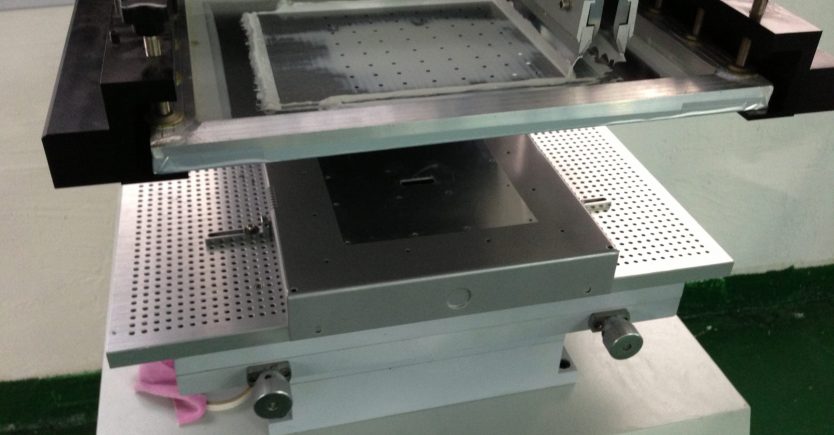

Thermal Paste

The thermal paste we use is a ceramic-based, polysynthetic compound. The compound is used to ensure maximum thermal transfer from the LED to the heatsink, lowering operating temperatures and improving efficiency. Our custom designed semi-automated machines dispense the compound with precision and speed. This process has greatly improved long term reliability of eLuminaire fixtures.